- Hello, Welcome to Alumetal website.

- +86-21-68406009

- elsa@alumetal.net.cn / wrm5@vip.sina.com

lilian@alumetal.net.cn

|

1.Saw cutting It can be easily processed with wood product processing saw and plate saw. It's recommended to use hard alloy blade. |

|

|

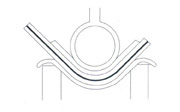

2.Slotting It's important to make the V type slotting process with a distance of 0.2-0.4mm from the polyethylene substrate. The recommended slot angle is 110. ① milling machine and trimmer Use the modified drill as showed in the left chart. Running speed: 20000-30000rpm Feed speed:3-5m/min Material:hard alloy ② When processing large quantity of V type slots it's recommended to use round saw and belt saw. And the following is an example ofslotter: * material:hard alloy flake * outer diameter:305mm * number of teeth:24 * running speed:3000-5000rpm * feed speed:5m/min |

|

|

3.Bending with panel folder If operated on the platform, bending part can be made very tidy. |

|

|

4.Bending with panelbender When plate folder is used to finish the Wenling (New Lucky) panel,dies shall be placed on with appropriate radius. |

|

|

5.Bending with 3-roller panel bender 3-roller panel bender is more preferable for bending of large internal diameler to plate |

|

|

6.Riveting Countersunk rivet can realize easy. |

|

|

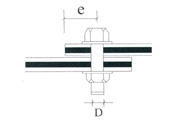

7.Bolting Considering from deformation limit, formul e>2D is the best calculation way of apertureD and distance from hole center to plate end. |

|

|

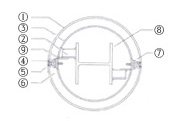

1.Example of panel type and joint design (A) Angle aluminum and seal joint(l) ① Alumetal Panel ② Aluminum rivet ③ Angle aluminum ④ Angle aluminum ⑤ Bach spacer ⑥ Sealing material ⑦ Spacer ⑧ Angle bar ⑨ Bullen screw |

|

|

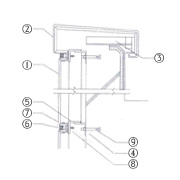

2.Example of column covering ① Alumetal Panel ② Angle support ③ Steel plate strip ④ Sealing material ⑤ Plastic lining bar ⑥ Accessories ⑦ Bullen screw ⑧ Bearing strut ⑨ Angel bar Above mentioned accessories are used for low buildings. |

|

|

3.Installation example of building top ① Alumetal Panel ② Building top ③ Angle support ④ Angle support ⑤ Angle bar ⑥ Sealing material ⑦ Lining material ⑧ Bullen Screw ⑨ Built-in anchoring or expanding bolt |

|

|

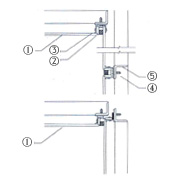

4.Installation example of external corner ① Alumetal Panel ② Sealong material ③ Lining material ④ Angle bar ⑤ Steel plate strip |

|

|

5.Installation example of internal corner ① Alumetal Panel ② Sealong material ③ Lining material ④ Angle bar ⑤ Bullen screw |

|

|

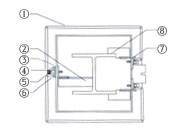

6.Example of strut covering ① Alumetal Panel ② Angle support ③ Angle bar ④ Sealing material ⑤ Plastic lining bar ⑥ Accessories ⑦ Bullen screw ⑧ Bearing strut Above mentioned accessories are used for low bulidings |

|